Formulation optimization of polyaspartic is a precise, systematic

process aimed at balancing performance, application properties,

cost, and environmental requirements. The core of this process

involves adjusting component ratios, incorporating functional

additives, selecting novel raw materials, and optimizing process

parameters to enhance the overall performance of the coating.

Core Component Optimization

1. Selection and Combination of Polyaspartic Ester Resins

Reactivity Control:

Selecting resin combinations with varying substituents (R1, R2) and

molecular weights (e.g., fast-curing plus slow-curing) precisely

controls gel time (adjustable from minutes to tens of minutes).

Optimization Direction:

Extending application windows while ensuring quick drying (walkable

in 1-2 hours).

Performance Balance:

- Hardness vs. Flexibility: Highly branched resins provide hardness, while long-chain resins

enhance flexibility and low-temperature impact resistance (e.g.,

coatings for wind turbine blades must withstand impacts at -40°C).

- Chemical Resistance: Selecting cycloaliphatic amine structures (such as IPDA

derivatives) to improve solvent resistance.

Innovative Strategies:

- Blending Modification: Blending with small amounts of hydroxyl-functional resins

(polyester, acrylate) or epoxy resins to improve adhesion or reduce

costs (compatibility and reaction mechanisms must be considered

carefully).

2. Selection of Polyisocyanates (-NCO Component)

Influence of Types:

- HDI trimer: Mainstream choice; excellent weather resistance,

moderate viscosity.

- IPDI trimer: Higher hardness and better heat resistance, but higher

viscosity and cost.

- Mixed trimer: HDI/IPDI mixtures balance performance and cost.

NCO:NH Ratio (Equivalent Ratio, Typical 1.0:1.0):

- Ratio >1.0: Higher crosslink density, increasing hardness and

chemical resistance but potentially reducing flexibility.

- Ratio <1.0: Retains more secondary amine groups, increasing

flexibility but potentially compromising solvent resistance.

Key Additive System Optimization

1. Rheology and Leveling Control

2. Curing and Catalyst Systems

Catalyst Selection:

- Divalent Organotin (DBTL): Efficient but environmentally problematic (increasingly

restricted).

- Metal-free Catalysts (e.g., tertiary amines): Environmental trend—such as DABCO or DMDEE—amount optimization

required to avoid brittleness.

- New Eco-Friendly Catalysts: Bismuth-zinc complexes (e.g., Borchi Kat 315), balancing activity

and environmental concerns.

Optimization Strategies:

- Low-temperature curing: Increasing catalyst dosage or using

low-temperature active catalysts (e.g., DMDEE) for application

below 5°C.

- High-temperature pot-life control: Reducing catalyst dosage or

adding retarders (e.g., acidic phosphate esters).

3. Improving Weatherability and Stability

UV Protection:

- UV Absorbers: Benzotriazoles (e.g., Tinuvin 1130) absorbing UVB/UVA.

- HALS (Hindered Amine Light Stabilizers): Such as Tinuvin 292, neutralizing radicals to prevent yellowing

(use cautiously with acidic substances).

Thermo-oxidative Stability:

- Adding antioxidants (e.g., Irganox 1010).

Storage Stability:

- Moisture Scavengers: Adding molecular sieves (e.g., Baylith L Paste) to prevent

NCO-water reactions.

- Dispersion Stability: Polymer dispersants (e.g., BYK-163) preventing pigment and filler

settling.

Pigment and Filler System Design

1. Functional Fillers Application

2. Pigment Selection and Dispersion

Weather Resistance:

Selecting inorganic pigments (e.g., titanium dioxide, iron oxides)

or high-performance organic pigments (e.g., quinacridone red).

Dispersion Process:

- Grinding with zirconia or glass beads in high-speed dispersers to a

fineness ≤20μm.

- Selecting dispersants with appropriate anchoring groups (e.g.,

BYK-110 for inorganic pigments).

Environmental and Cost Optimization Strategies

1. High-Solids/Solvent-Free Systems

- Resin Viscosity Reduction: Selecting low-viscosity polyaspartic esters.

- Reactive Diluent: Adding small amounts of mono-functional polyaspartic esters or

low-viscosity isocyanates (e.g., HDI monomer) to reduce viscosity

without compromising crosslinking.

2. Bio-based/Renewable Raw Materials

- Bio-based Resins: Partially bio-based polyaspartic esters derived from plant-oil

modified polyols (e.g., BASF’s partially bio-based products).

- Natural Fillers: Using renewable fillers like bamboo powder or rice husk ash

(addressing water-resistance issues required).

3. Cost Control

- Filler Substitution: Partial replacement of quartz sand with calcium carbonate

(controlling proportion to avoid hardness loss).

- Localized Sourcing: Using domestic high-performance polyaspartic resins to reduce raw

material costs.

- Simplified Formulation: Experimentally reducing additive variety (multi-functional

additives replacing single-function additives).

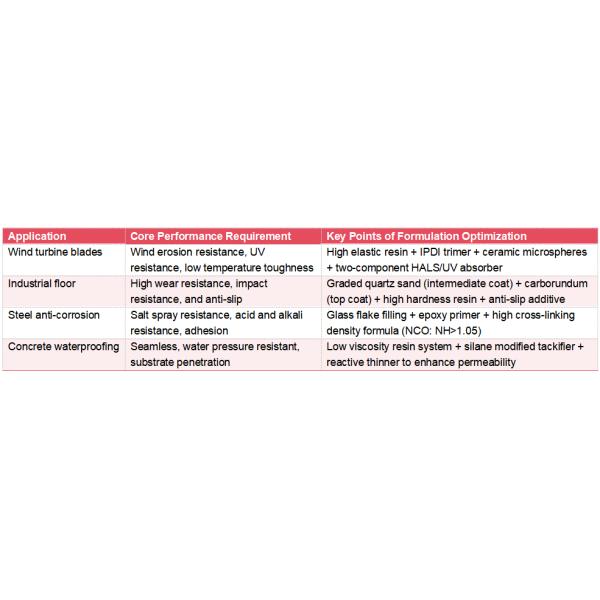

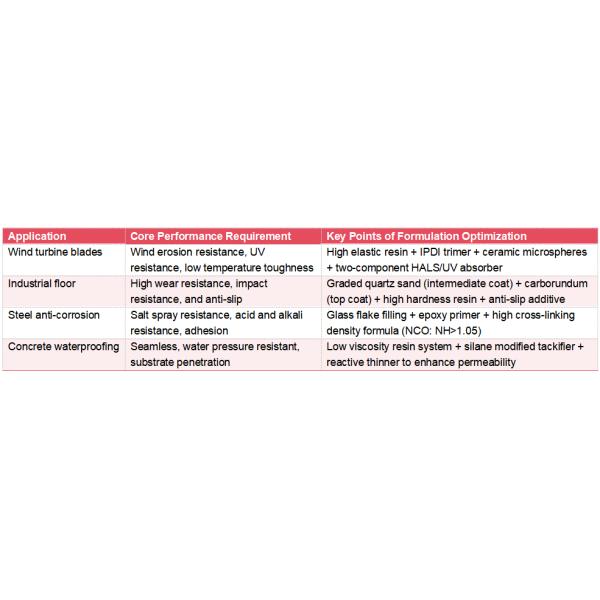

Scenario-specific Optimization

Experimental Validation and Characterization Methods

Rigorous testing required for optimization:

- Application Properties: Gel time (GB/T 7123), pot-life, sagging limits (ASTM D4402).

- Mechanical Properties: Hardness (Shore D, ISO 868), abrasion resistance (Taber, ASTM

D4060), adhesion (pull-off method, ISO 4624).

- Weatherability/Chemical Resistance: QUV aging (ASTM G154), salt spray test (ISO 9227), chemical

resistance immersion tests (acids, bases, solvents, ISO 2812).

- Microstructural Analysis: SEM for filler dispersion, DSC for glass transition temperature

(Tg), FTIR for curing degree.

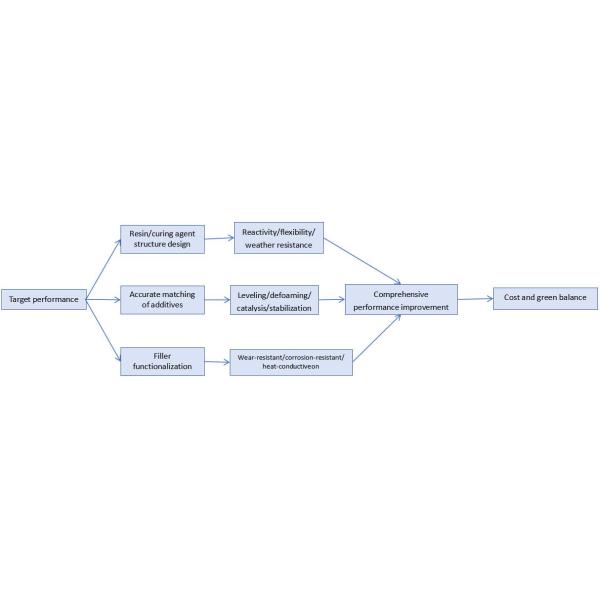

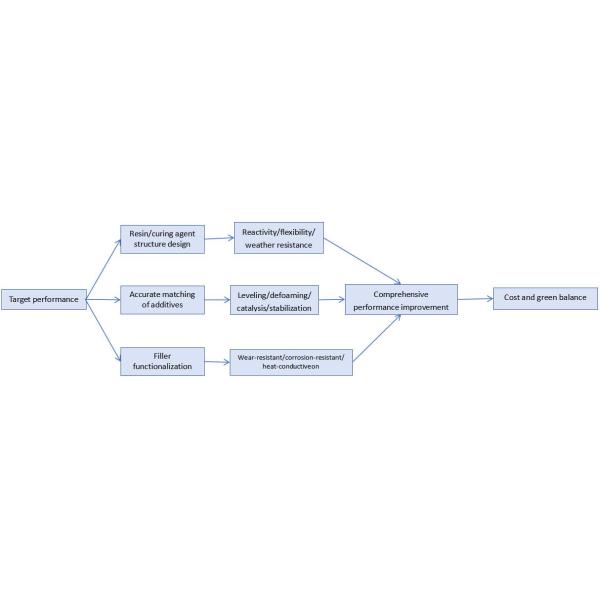

Core Logic of Formulation Optimization

Keys to Successful Optimization

Precise Requirement Definition: Clearly prioritizing coating core performance (e.g., abrasion

resistance for flooring, impact resistance for wind power).

Synergistic Component Interaction: Avoid additive interactions canceling out benefits (e.g.,

excessive silane leveling agents can reduce adhesion).

Dynamic Iteration: Rapid optimal ratio screening via DOE (Design of Experiments),

combined with validation in application scenarios.

Through continuous optimization, polyaspartic is progressively

surpassing performance limits, advancing towards higher durability,

smarter construction, and greater environmental sustainability.

Feiyang has been specializing in the production of raw materials

for polyaspartic coatings for 30 years and can provide polyaspartic

resins, hardeners and coating formulations.

Feel free to contact us: marketing@feiyang.com.cn

Our products list:

Contact our technical team today to explore how Feiyang Protech’s

advanced polyaspartic solutions can transform your coatings

strategy.

Contact our Tech Team